From raw material to product

It used to be common practice to dump waste and leave it to its own devices. This type of disposal has been banned since 2005, not least due to the release of large quantities of greenhouse gases. Even before that, people were already thinking about how to gain added value from the unavoidable evil of residual waste. The answer is: thermal waste treatment with the support of Reitz fans.

From raw material to product

In thermal waste treatment, residual waste is incinerated with virtually no residue in order to use it as an energy source. If the heat from the waste fire converts water into steam and this is then converted into electricity and district heating, as the Bonn waste recycling plant does in conjunction with the Stadtwerke Bonn combined heat and power plant, waste can supply a small town.

The calorific value is not far below that of fossil fuels, but in contrast to these, it can still be described as a renewable raw material due to our consumption. After incineration, pollutants have to be purified from the flue gases at great expense. It is impossible to imagine this process without fans. If all that comes out of the chimney at the end of the process is a gentle breeze that contains less particulate matter than the ambient air, then Reitz has also made a contribution.

Combustion and the associated

energy generation through water vapor

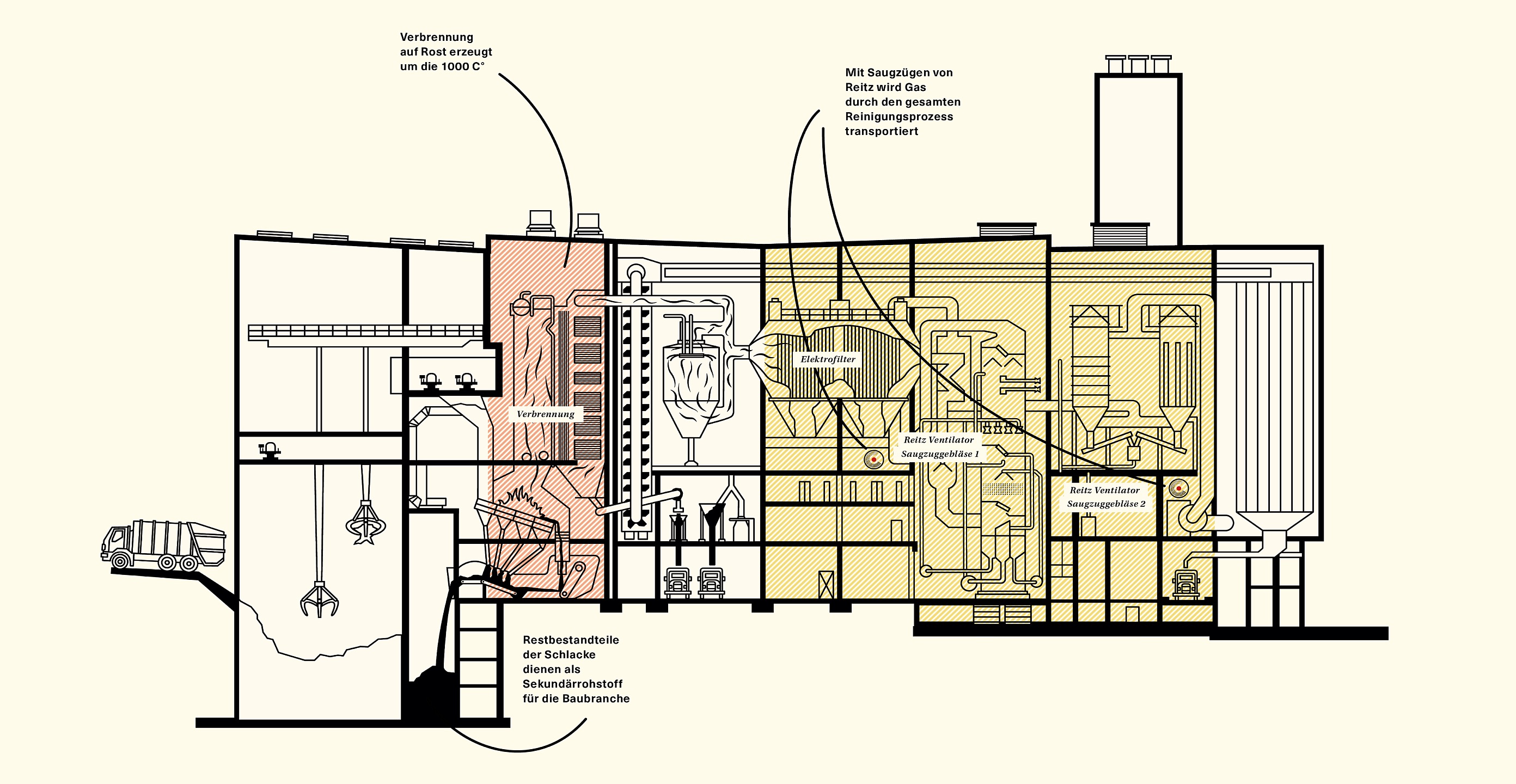

At the beginning of the recycling process, the waste that cannot be recycled in any other way is poured from the refuse trucks into the waste bunkers at tipping points, where it is mixed with a remote-controlled gripper arm and finally filled into the incineration plant. Here, drying with preheated air ensures that the waste burns really well on the moving grate of the main incineration zone, usually without fossil fuel accelerators, at a constant 1,000 C°. This heat is used in the steam boiler system to produce steam at a temperature of around 400 C°, which is fed to the combined heat and power plant via a pipe system. There, turbines produce electricity for the grid and the waste heat is fed into the district heating network.

The flue gas is purified to such an extent

that almost fine dust-free air is emitted.

There are several methods for flue gas cleaning. MVA Bonn has opted for multi-stage, wet flue gas cleaning, in which pollutants and dust are removed from the flue gas in several filter stages, for example with a flue gas scrubber or electromagnetically with an electrostatic precipitator. The gas is transported through this entire cleaning process with suction hoists from Reitz until, at the end, only slightly heated air is released from the chimney into the environment.

What remains of the combustion process:

slag, ash, flue gas

The aim of the plant is to produce as little residue as possible and to treat it so that it can be recycled. The result is impressive, as virtually nothing is left over at the end. The slag produced during incineration is processed by a subsidiary company. First, all the raw materials are filtered out for recycling, after which the residual components of the bottom ash are used as secondary raw materials for the construction industry, among other things.