Retrofit

Reitz Retrofit

portfolio

We support operators in modernizing their systems with tailor-made retrofit solutions.

01

Optimization of ventilation systems

We increase the performance, energy efficiency and reliability of your ventilation systems. After a thorough analysis, we identify bottlenecks and develop tailor-made solutions to improve air flow and reduce energy consumption.

02

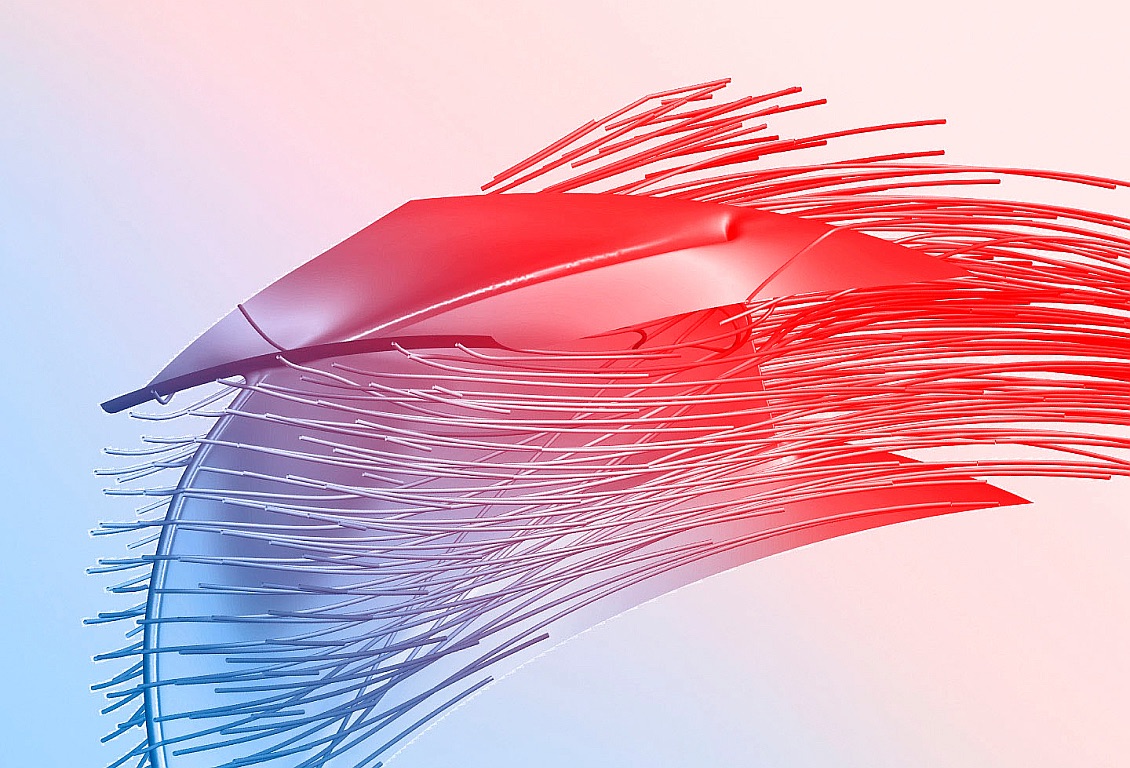

CFD analysis

Our CFD (Computational Fluid Dynamics) analysis examines the flow behavior of fans and ventilation systems in detail. Using advanced simulation software, we analyse pressure distribution, velocity profiles and turbulence in order to optimize efficiency and identify possible design improvements. Our experts use the results to specifically optimize your system.

03

Ventilation measurements

Our air technology measurements based on DIN ISO 5802:2016-02 provide in-depth analyses of the performance of your fans and systems. We record volume flow, pressure, speed and performance with high-precision measuring devices. The data obtained helps to identify performance losses and increase efficiency, resulting in energy savings and reduced operating costs.

04

Noise measurement

We analyze and evaluate sound problems in industrial environments using specialized sound measurement equipment. By accurately recording sound levels and frequencies, we identify noise sources and provide customized solutions to reduce noise pollution to ensure a safe and comfortable working environment.

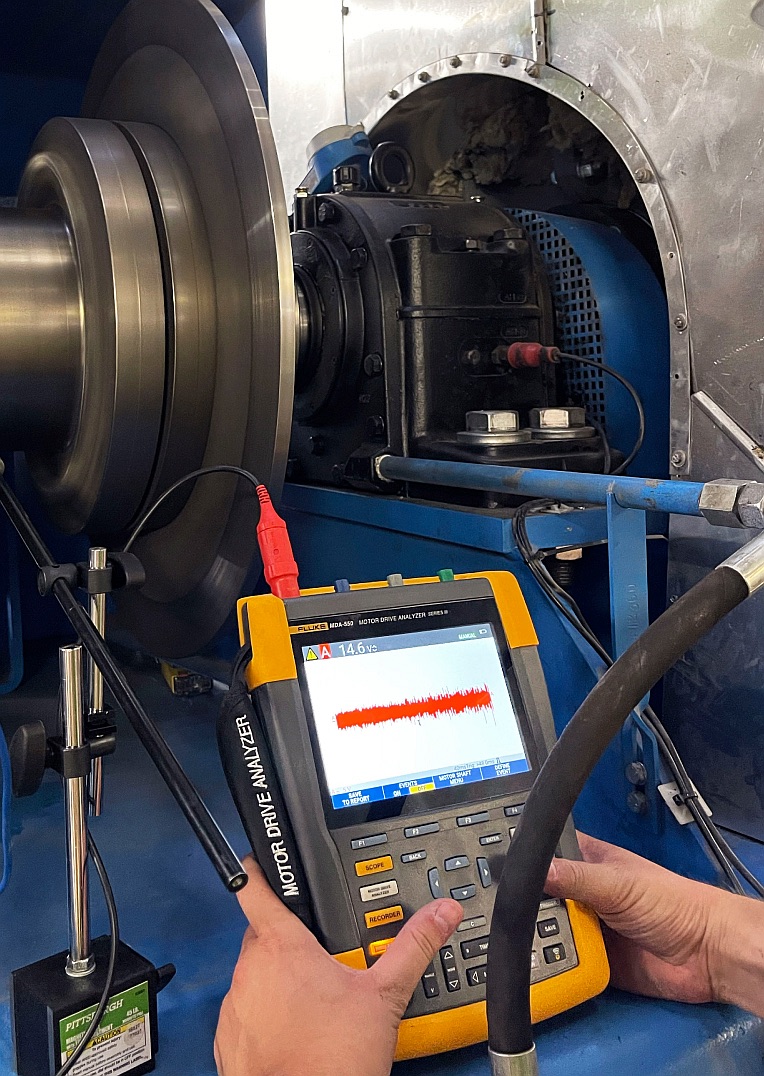

05

Vibration analysis

Our vibration analysis services help to avoid downtime and increase plant availability. By analyzing vibration patterns during operation, we can detect damage caused by stress or design defects at an early stage. Regular measurements enable the progress of damage to be assessed and maintenance and inspection cycles to be organized flexibly. Our services include the metrological recording of vibration behavior, the evaluation of vibration spectra and the determination of the causes of damage. The cause of the vibrations is often unknown – here we support you in investigating the cause and offer recommendations for optimizing your systems.

06

Thermography

Our thermography services include the inspection of fans and control cabinets to detect overheating and defective components at an early stage. We use thermal imaging cameras to identify hotspots that indicate potential problems, enabling preventive maintenance measures to be taken. Regular inspections ensure the optimal functioning and safety of your systems, reduce the risk of breakdowns and extend the service life of your systems. Rely on our expertise to ensure the efficiency and safety of your industrial systems.

07

Energy consulting

Increasing energy efficiency is cheaper than you think. Even small investments can improve your efficiency and reduce operating costs. Our energy consulting service offers a comprehensive analysis of your energy consumption and the energy efficiency of your systems. Trained and listed energy consultants in accordance with BAFA guidelines record precise data on site and identify potential energy losses. We offer profitability analyses and tailor-made solutions to reduce your energy costs and increase the efficiency of your system.

Energy consulting in the form of an energy audit is subsidized by the Federal Ministry of Economics and Climate Protection (BMWK)

Our services:

- Energy audits in accordance with DIN EN 16247: Identification of potential savings and measures to increase efficiency.

- Comprehensive analysis of weak points: Detailed information on energy losses.

- Profitability analysis: Evaluation of the cost efficiency of energy-saving measures.

- Concrete recommendations for action: Measures to save energy and increase efficiency.

08

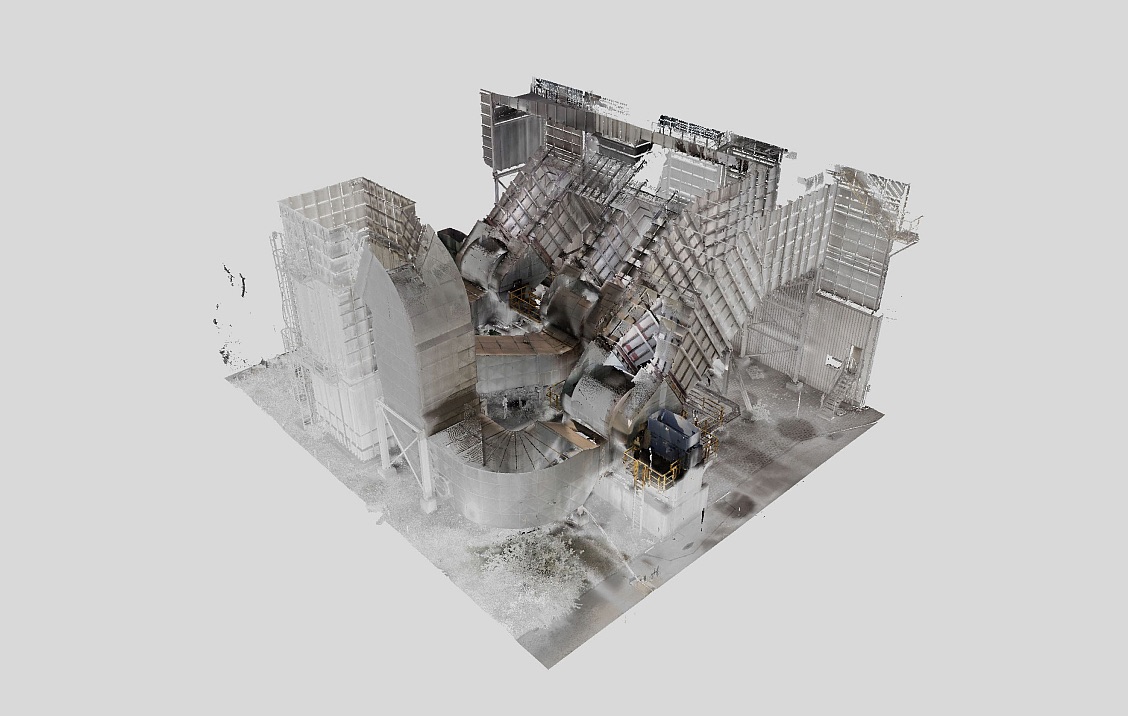

3D laser scanning

This technology allows us to create high-precision 3D models that support the efficient planning and implementation of customized retrofit solutions. First, our experienced technicians carry out precise on-site scanning to quickly and efficiently record your existing systems and structures. We then carefully process the collected data, create detailed solution approaches and support you from planning to final implementation.

09

Project planning

We support you in the planning of all types of optimization projects. Project planning is a central component of our services. Our process begins with a thorough needs analysis to precisely define the specific goals and requirements of your retrofit project. Based on this analysis, we develop customized solution concepts. To ensure smooth execution, we draw up detailed schedules and resource plans to ensure that your project is implemented on time and cost-effectively.

Our technical experts are at your side throughout the entire planning process and offer you comprehensive advice and technical expertise. In addition, we support you not only with the planning, but also with the implementation of your retrofit project. We carefully monitor progress to ensure that all defined objectives are met and your plant is successfully modernized. With our experience and commitment to quality, we are your reliable partner for the modernization of your plant.

Innovative special solutions

High-pressure fans

Our high-pressure fans have been specially developed for natural gas and hydrogen calibration points and are used in various gas test benches around the world. They are designed for pressure ratios of up to 100 bar and, in combination with our coordinated heat exchangers, ensure optimum conditions in your high-pressure test bench. Each fan is individually designed for your system, taking into account all norms and safety standards. We take changing energy trends and technologies into account and plan to design our high-pressure fans for use with hydrogen in the future.

Gas test benches

Our test benches are customized solutions that are precisely tailored to the high demands of gas meter testing. With our test benches, large gas meters can be calibrated or verified in accordance with official specifications. Thanks to state-of-the-art technology, we guarantee constant conditions to ensure high measurement accuracy.

In the planning phase, we use CFD (Computational Fluid Dynamics) analyses to design the optimum system structure. In combination with our high-pressure fans, we offer you a complete system that ranges from EMSR technology (electrical measurement and control technology) to refrigeration technology and commissioning.

Each gas meter test bench is individually planned, designed and installed to meet the highest measurement and safety standards and ensure reliable performance.

Air preheater cleaning

Our mechanical Luvo cleaning increases the service life and effectiveness of your smooth-tube heat exchangers. The cleaning system regularly and effectively removes matted dust particles and deposits “online”, which adhere to the hot tubes of the air preheater and build up in layers. It minimizes soiling and extends the service life of your heat exchangers. This ensures optimum heat transfer and thus reduces operating costs.

The implementation can be carried out as a new delivery of the heat exchanger including cleaning and as a retrofit in existing systems.

Electrical engineering

and EMSR technology

Our system solution in electrical and instrumentation and control technology comprises a comprehensive complete solution for controlling and monitoring fans in ventilation systems.

The solution comprises the following components:

- Transformer, frequency converter and motor form a coordinated system that is assembled specifically for use in your system.

- Integrated measuring systems for monitoring volume flow, temperature and vibrations to ensure optimum operation and enable seamless operational monitoring.

- Individually created PLC programs for precise control and automation of the fans.

- We offer user-friendly visualization solutions for easy monitoring and operation of the systems.

The system is individually planned and adapted to the specific requirements of our customers. It provides an efficient and reliable solution for the operation of fans in various applications by ensuring seamless integration of all necessary components.