Smart Solutions

Shafts of

offset design

Your challenges, our solutions.

Minimise the risk

of unplanned stop

Imagine the impeller hub is so tightly connected to the shaft that it cannot be removed from the shaft even with special tools. In these cases, the shaft must be cut off which inevitably results in replacement of the shaft and possibly even the impeller. The consequences are severe: unpredictably long downtimes and unexpectedly high costs.

Our solution of a stepped shaft significantly minimises this risk and ensures a smooth and efficient maintenance process.

Advantages at a glance

Faster and easier maintenance:

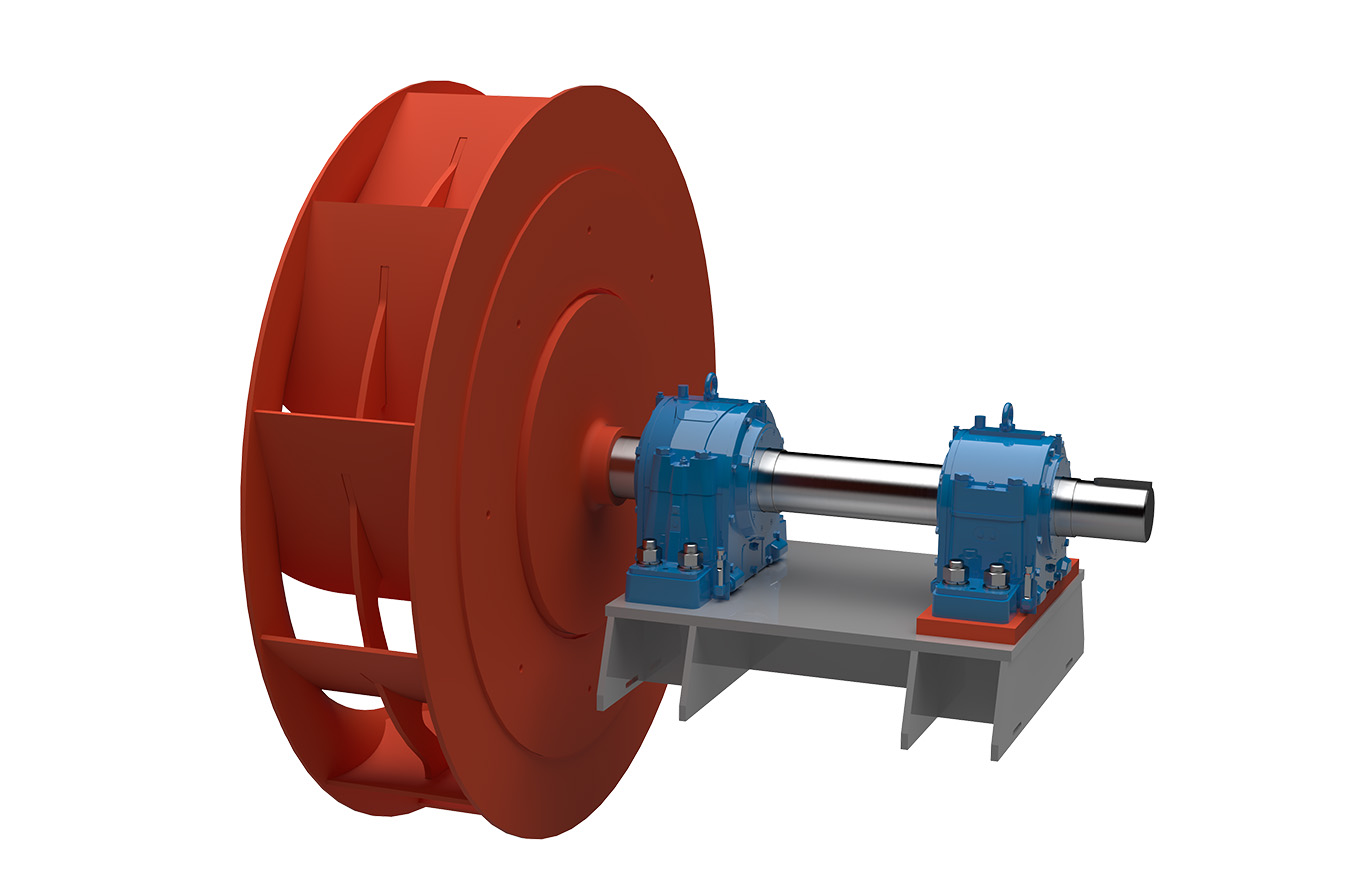

Dismantling the bearing via the drive side significantly reduces maintenance times. At the same time, the impeller remains mounted on the shaft, simplifying the maintenance process and minimizing the risk of damage.

Cost and effort savings:

Faster disassembly and maintenance requires no special tools, resulting in lower costs. In addition, the cover or intake can often remain mounted, reducing the effort and minimizing the risk of damage.

Minimized downtime & higher reliability:

Shorter assembly times lead to reduced downtime and a quicker return to service. Fewer work steps and less wear and tear on components ensure long-term cost savings and greater system reliability.

The driving shaft is turned in a stepped or offset design where the diameter continually decreases from the non-driven side towards the driven side. The result is that the bearing of the non-driven side (impeller side) shows a higher diameter than that of the driven side. This design offers dismantling of both bearings from the driven side.

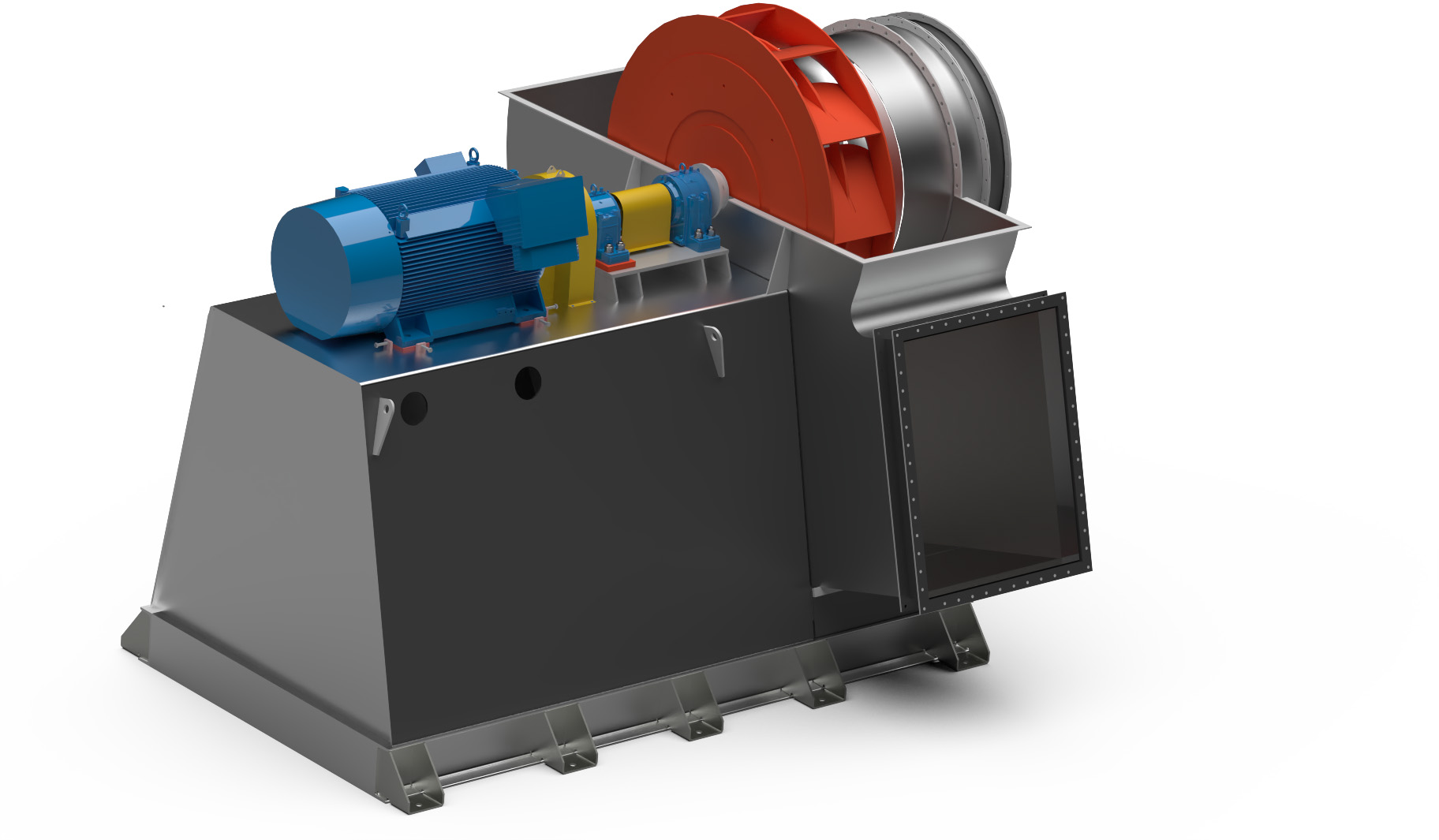

Disassembly concept for bearing replacement

1. The impeller (1) is unhooked using a stop tool.

2. The motor (5) is released, pulled backwards and rotated by 90°.

3. Pull off the coupling (4) in the direction of the motor.

4. Pull off the fixed bearing (3) in the direction of the motor.

5. Pull off the floating bearing (2) in the direction of the motor.

* Reassembly is carried out in reverse order *

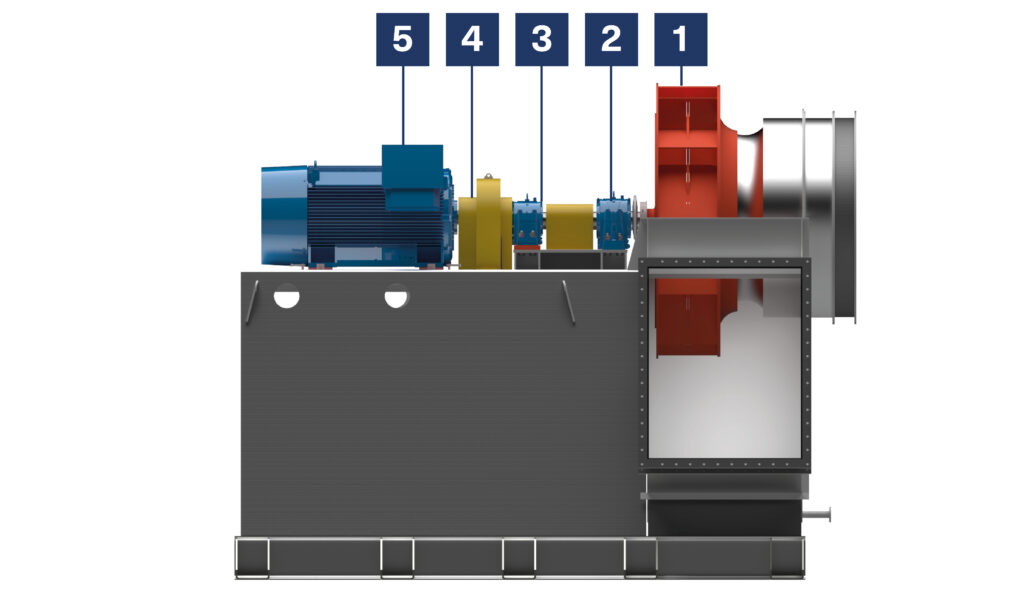

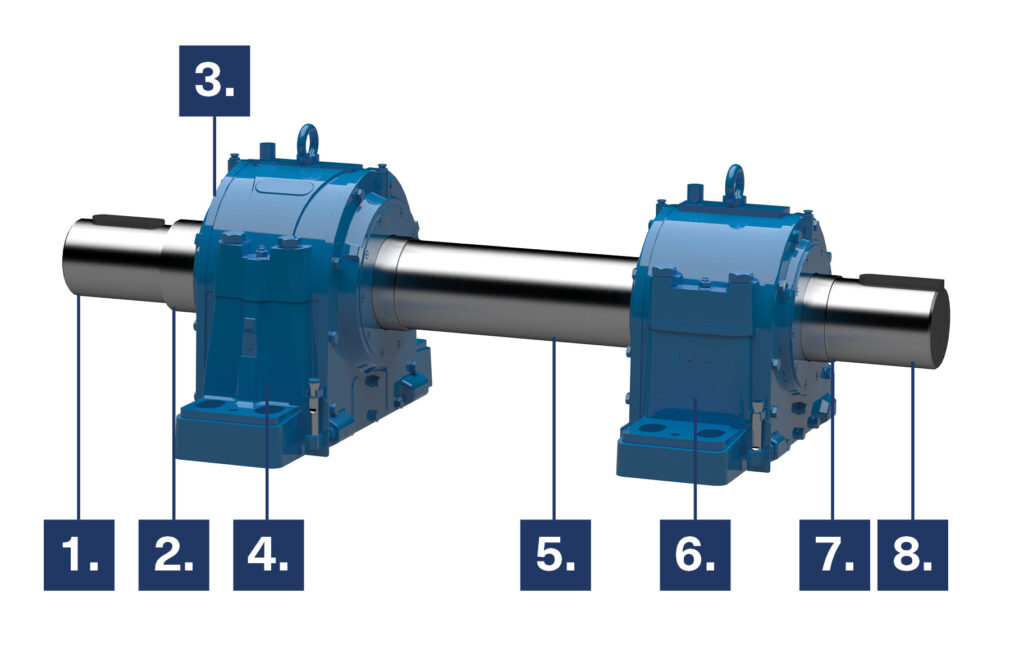

Offset shaft design (example)

1. Impeller side

2. Rear wall of housing

3. Shaft diameter Ø 126 mm

4. Position bearing | Ø 120 mm

5. Shaft diameter Ø 116 mm

6. Position bearing | Ø 110 mm

7. Shaft diameter Ø 107 mm

8. Coupling side