Equipment & Accessories

Sensors & monitoring

Maximum plant availability through intelligent sensor solutions

Our modular monitoring systems enable you to detect deviations in good time, respond in a targeted manner, and thus ensure the trouble-free operation of your plant on a permanent and future-proof basis.

Advantages at a glance

Maximum system availability: Defects are detected early, preventing downtime.

Lower maintenance costs: Maintenance based on demand instead of emergency callouts.

Longer service life: Protection of bearings and components.

Flexible retrofitting: Retrofitting also possible for existing systems without the need for new construction.

Comprehensive solutions: Customized sensor technology for your requirements.

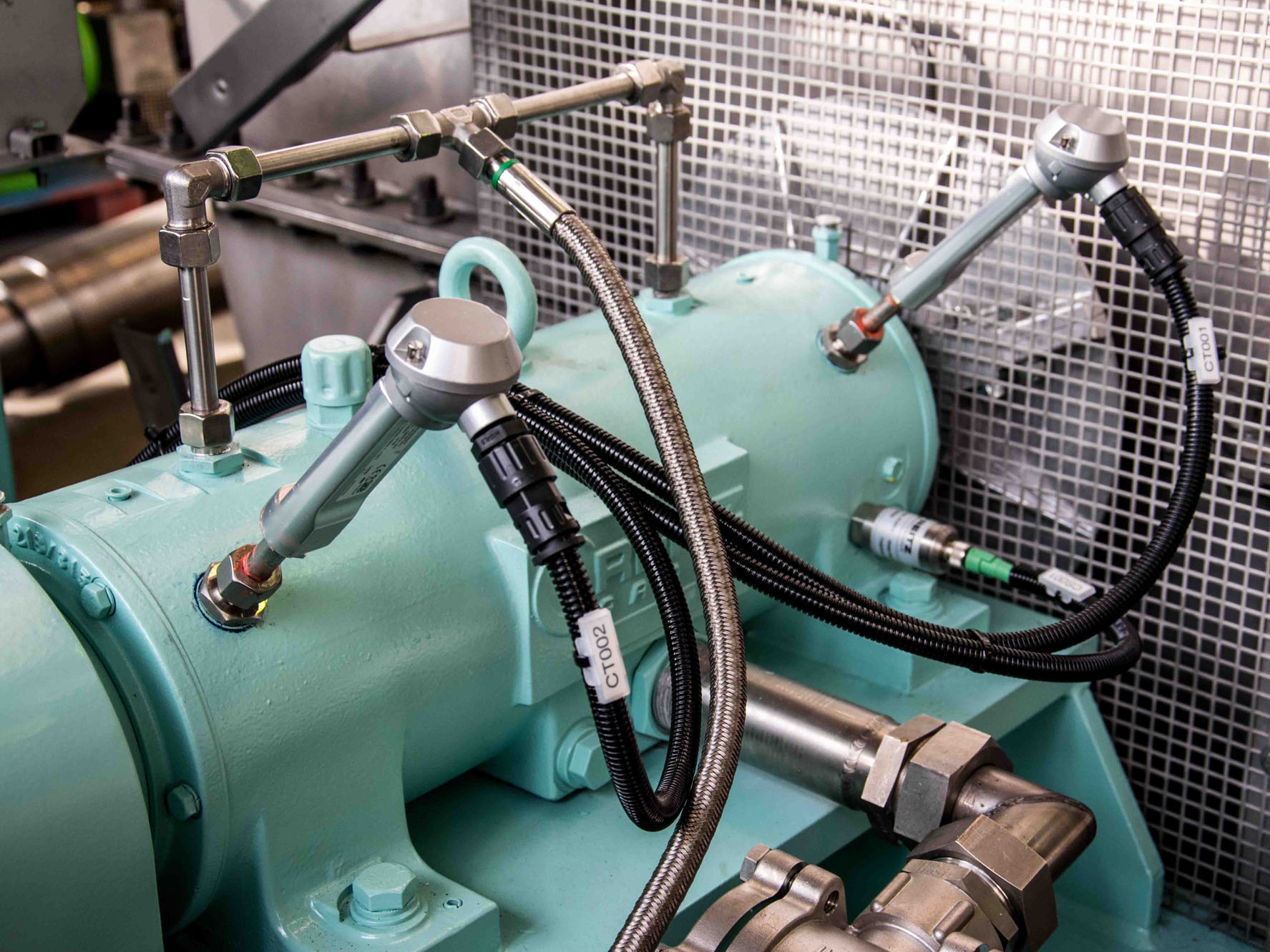

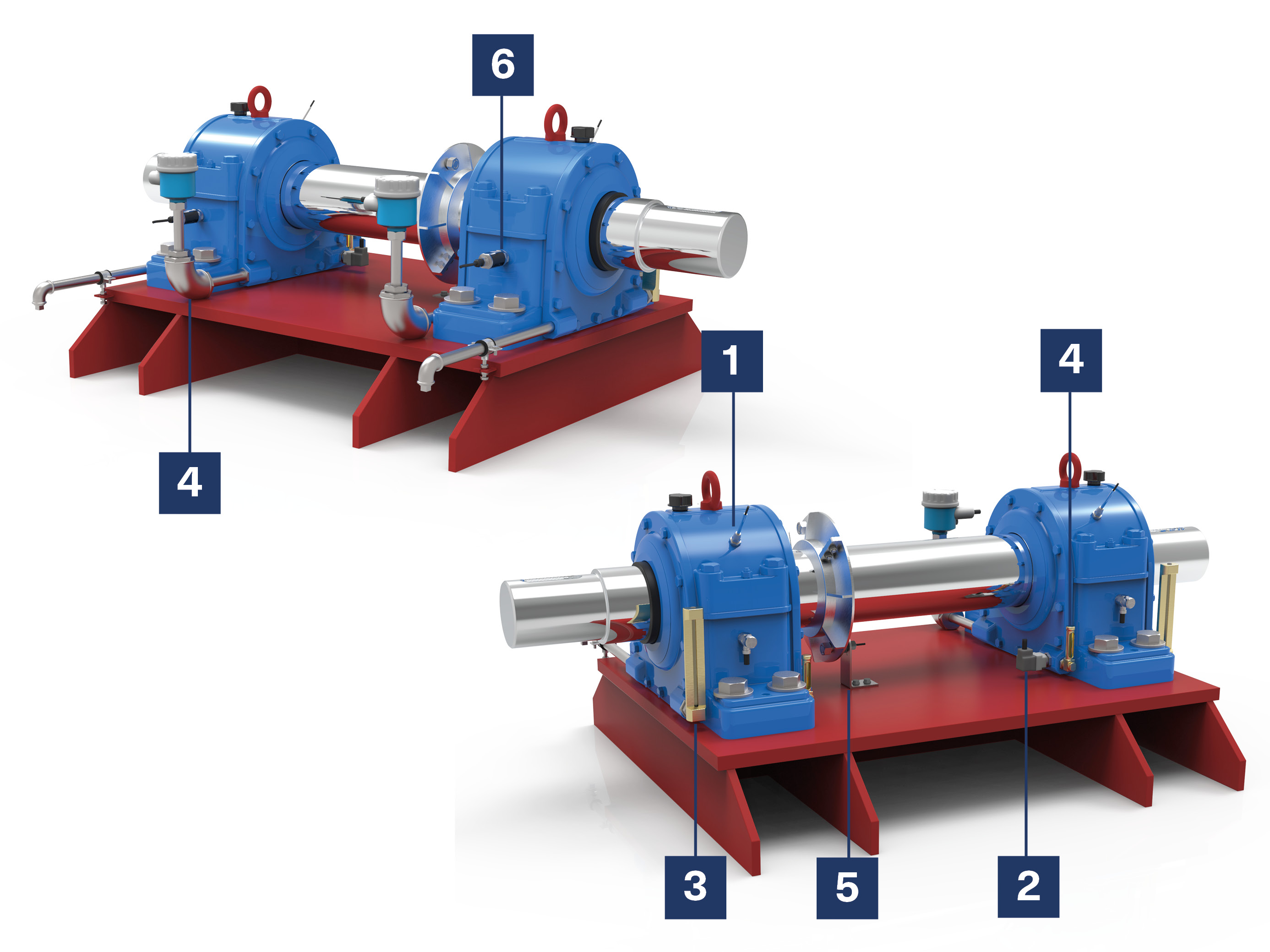

Bearing temperature monitoring

(1) Monitoring bearing temperature is crucial to prevent overheating and resulting damage to your fans. Our high-precision temperature sensors continuously record the temperature of the bearings and alert you in the event of deviations so that you can intervene in good time.

Monitoring the wear on bearings

(2) Bearings are one of the most heavily stressed components of fans. Our monitoring devices detect signs of wear at an early stage and give you the opportunity to take maintenance measures in good time. In this way, costly failures can be avoided and the service life of your fans can be extended.

Monitoring the lubricant temperature

(3) In addition to the fill level, the temperature of the lubricant is also a critical factor. Our sensors continuously measure the lubricant temperature and immediately detect when temperatures are outside the optimum range. This helps to prevent overheating and premature ageing of the lubricant.

Monitoring the lubricant fill level

(4) A sufficient lubricant level is crucial for the longevity and performance of your fans. Our sensors monitor the lubricant level in real time and warn you when refills are required. This prevents damage caused by insufficient lubrication and ensures the smooth operation of your systems.

Speed monitoring

(5) Precise speed control is of great importance for the efficient operation of your fans. Our speed sensors continuously monitor the speed of your fans and alert you in the event of deviations from the target value. This ensures optimum performance and protects against overloading or mechanical damage.

Monitoring bearing vibration

(6) Increased vibration in bearings can indicate imbalance, misalignment or other problems. Our vibration sensors precisely detect any changes in the vibration behavior of your bearings and enable proactive maintenance. This prevents major damage and unplanned downtime.

Are you familiar with our active balancing system?

Learn more

Infomaterial